You use an automatic power factor controller to help your electrical system work well. This device checks the power factor and manages reactive power right away. When you use an APFC, your equipment can last longer and you do not waste energy. New studies show these controllers help save energy by cutting power losses and making costs lower. With better control, you also do not get extra fees from your energy provider.

An automatic power factor controller helps save energy. It controls reactive power. This can lower your electricity bills.

Keeping a high power factor stops energy waste. It helps machines last longer. It also avoids extra charges from your energy company.

Check your power factor often. Use smart meters to find problems early. This keeps your system working well.

Pick the APFC panel that fits your needs. Some work best for steady loads. Others are better for loads that change quickly.

Using an APFC system saves money. Many companies get their money back in 18 months.

You often hear about power factor in electrical systems. Power factor tells you how well you use electricity. It compares the real power you use to all the power given to you. Look at the table below for the main formulas:

Definition | Formula |

|---|---|

Power Factor as Cosine of angle between Current and Voltage | Cosθ = P ÷ V I or Cosθ = kW ÷ kVA |

Power Factor as Ratio between Resistance and Impedance | Cosθ = R ÷ Z |

Power Factor as Ratio between Active Power and Apparent Power | Cosθ = P ÷ S or Cosθ = kW ÷ kVA |

A high power factor means you use electricity well. A low power factor means you waste energy and put more load on your system.

You want your system to work well and save energy. If power factor goes down, your system needs more apparent power. This makes more losses and puts more work on wires and transformers. You might see voltage drops and machines that do not work right. Keeping power factor high helps wires carry more current and lowers losses. It also helps your machines last longer and keeps you from paying extra charges.

Tip: Fixing power factor early helps you control demand and save energy.

Power factor correction has many good points. You use less apparent power, so your electric bill is lower. You also lose less energy in your system. Many factories save 12% to 18% on their bills after fixing power factor. One study showed a factory saved about $6,200 each month by raising power factor from 0.72 to 0.95. Most companies get their money back in about 18 months. You also avoid fines for low power factor and keep your system safe from too much load.

Power factor correction lowers demand and losses.

You save energy and money.

Your machines work better and last longer.

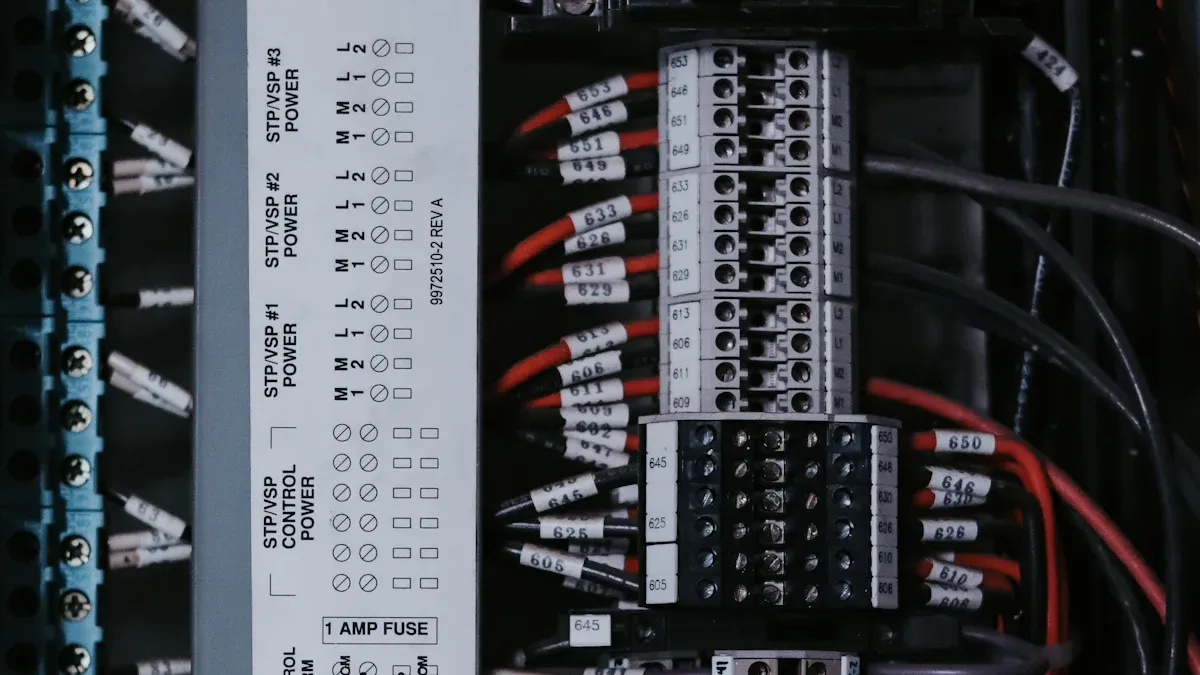

An automatic power factor controller has many important parts. Each part helps you make your power factor better. Here are the main things inside:

Capacitor banks help balance reactive power. You turn them on or off to fix your power factor.

The automatic power factor controller checks your power factor all the time. It chooses when to turn on the capacitors.

Relays and contactors connect or disconnect the capacitor banks. The controller tells these parts what to do.

A current transformer measures the current in your system. It sends this information to the controller so it can decide what to do.

Circuit breakers and fuses keep your system safe from too much power or problems.

The display meter shows you what is happening right now. You can see power factor, voltage, current, and if the capacitor banks are on or off.

Tip: Look at the display meter often. It helps you find problems early and keeps your system safe.

You use an automatic power factor controller to keep your power factor close to one. The controller watches your system all the time. If your power factor gets low, it turns on the capacitor banks. If your power factor gets high, it turns them off. This helps your system work better and lose less energy. The active automatic power factor controller works fast and changes things by itself. Some systems use a passive automatic power factor controller, but active ones work faster and handle changes better.

Advancement Type | Description |

|---|---|

IoT Connectivity | You can watch power quality and how capacitors work right now. |

Smart Sensors | You get data to find problems early and spend less on repairs. |

Data Analytics | You learn how you use energy and can plan for upgrades. |

Enhanced Predictive Maintenance | You find problems early and stop your system from breaking. |

Improved System Reliability | You fix things fast to stop failures. |

Customization and Scalability | You pick what works best for your needs. |

Integration with Smart Grid | You make the grid stronger and more efficient. |

Smart capacitor switching helps you control your system better. The automatic power factor controller uses real-time data to know when to turn on capacitors. You get quick control and can add more parts if you need them. This helps you handle more power and keep lines from getting too full as things change. The active automatic power factor controller reacts fast to changes in the grid. You get better efficiency and can control how power moves.

Note: APFC devices add voltage at a right angle to the line current. You can control power on your lines without building new ones.

This project can be made bigger with more SmartValves to let more power flow as more renewable energy is added in the future.

You can use new energy sources and move more power without building new lines. The automatic power factor controller helps you keep up with changes and makes sure your system works well.

You want your electrical system to work well. Automatic power factor correction helps you do this. Here are the steps you follow in real life:

Requirement Analysis

First, you check how much power you use. You look at your power factor. You decide what number you want to reach.

System Design

Next, you check your voltage levels. You pick the right parts for your system. You make sure everything fits together.

Controller Selection

Then, you choose an automatic power factor controller. This device watches your power factor. It makes changes right away.

Sensor Integration

You add sensors to your system. These sensors measure current and voltage. The controller gets good data from them.

Capacitor Bank Design

You design your capacitor bank. It adds or removes reactive power. This keeps your power factor close to your goal.

Control Strategy Development

You set up rules for your controller. The controller checks your power factor all the time. It turns capacitors on or off to help your system.

Tip: You can use these steps in a factory, office, or school. You save money and use energy better.

You use relays and smart logic to control your system. The APFC relay works like a switch. It connects or disconnects capacitor banks when your power factor changes. You get quick action and better control.

VarPlus logic helps you make smart choices. It checks your power factor and picks how many capacitors to turn on. You get smooth changes and no sudden jumps in your system. The logic uses real-time data from sensors. You see your power factor get better right away.

Component | Function |

|---|---|

APFC Relay | Switches capacitor banks on or off |

VarPlus Logic | Decides how many capacitors to use |

Sensors | Give real-time data for smart decisions |

Note: You can trust automatic power factor correction to keep your system steady. You get fewer problems and save more energy.

You see the good results every day. Your machines work better. You pay less for electricity. You do not get extra charges from your energy provider. You also help the environment by using less energy.

You need some main parts to set up an automatic power factor controller. Each APFC panel type has special features for managing power. The table below shows which panel might be best for you:

Type of APFC Panel | Features |

|---|---|

Contactor-Based APFC Panels | Old style switching, saves money, works for steady loads |

Thyristor-Based APFC Panels | New style switching, no sudden current, good for loads that change |

Hybrid APFC Panels | Mixes both types, switches fast and saves money |

Reactor-Based APFC Panels | Filters harmonics, lowers distortion, good for loads that are not steady |

Static VAR Generator (SVG) Panels | Fixes power factor right away, responds fast to load changes |

You also need current transformers, step-down transformers, microcontrollers, sensors, and display meters. These help you measure, control, and watch your power factor.

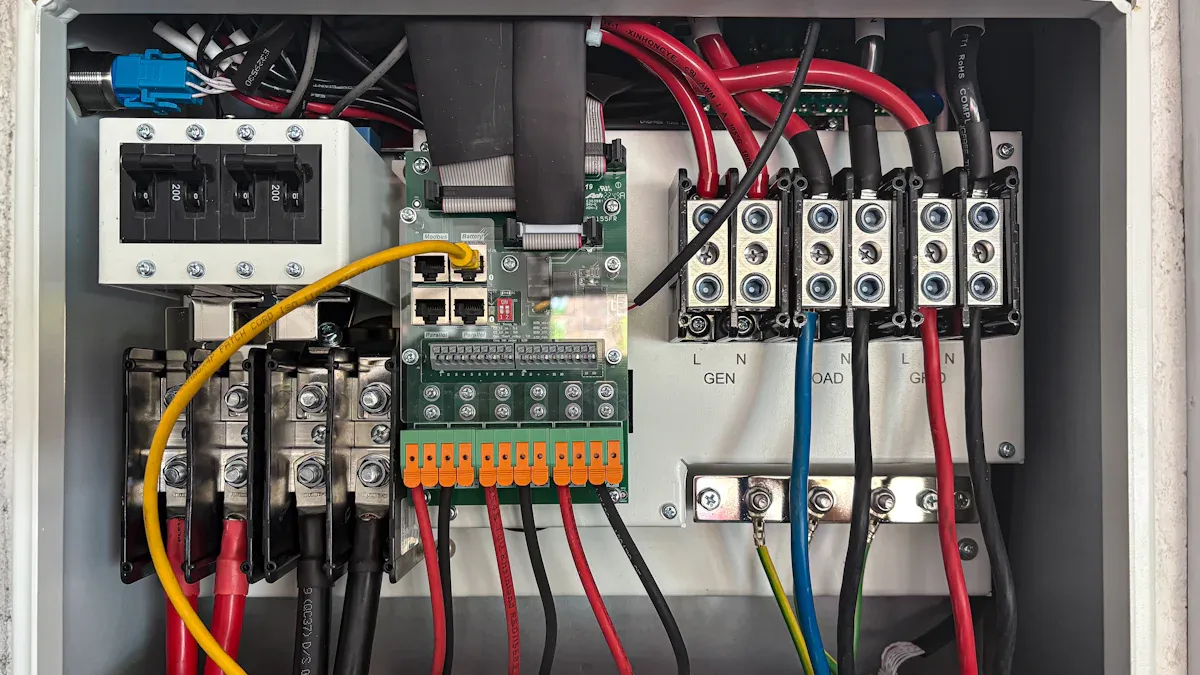

First, check what your power system needs. Measure your power factor and pick the APFC panel that fits best. Install current transformers to watch the current. Add step-down transformers to set the right voltage for the controller. Connect sensors and microcontrollers to collect data and control the capacitor banks. Set up the display meter so you can see your system working.

Put the APFC panel in a place with enough room. SmartValves and modular panels make setting up easier and faster. You can make your system bigger if you need more energy later. Test the system to make sure everything works well.

Tip: Modular APFC systems let you add more panels if your power needs change.

You keep your automatic power factor controller working well by using smart steps:

Check your system often to find power factor problems early.

Use smart meters to see changes in energy use.

Plan regular checks and reviews to make your power system better.

Make sure you have space for upgrades later.

Pick modular designs for easy changes and quick fixes.

Note: If you use a modular APFC system, your power stays on even if one part stops working.

You get better power factor, save energy, and avoid extra costs when you follow these tips.

Automatic power factor controllers are used in many industries. Utility companies use these systems to make power factor better. They also help lower power loss and keep equipment safe. Factories use APFCs to save money and use energy better. In places like malls and offices, APFCs help control power. They also stop you from getting fines from utility companies.

Application Type | Description |

|---|---|

Energy Management | APFC systems help you control reactive power and avoid extra charges for poor power factor. |

Commercial Buildings | You use APFCs in malls, offices, and big stores to optimize energy use. |

Smart Integration | Many buildings now connect APFCs with building management systems for better control. |

A mall in Europe saved 8% on its electric bill after using APFCs.

APFC systems give you many good things. They help you get a high power factor. This means you use energy in a better way. You waste less electricity and help the planet. This is good for the environment and supports green habits.

Benefit | Description |

|---|---|

Energy Efficiency | You use less energy and reduce waste. |

Environmental Impact | Lower energy use means less pollution and a smaller carbon footprint. |

Many countries have rules that ask you to use APFC systems. These rules help you manage power better and make power sharing easier.

You should know some limits of APFC systems. Capacitors need time to rest before you use them again. This can slow things down. Turning on capacitors can make big currents that hurt equipment. Sometimes, APFCs cost too much for some uses.

Think about these things when you choose an APFC system:

Consideration | Description |

|---|---|

Technical Specs | Check how fast and accurate the controller is. |

Industry Compliance | Make sure the system meets safety and quality standards for your sector. |

Performance Metrics | Aim for a power factor above 0.95 and smooth switching. |

Cost-Efficiency | Think about total costs, savings, and how long the parts will last. |

Integration | Make sure the system works with your current equipment and controls. |

After-Sales Support | Look for good customer service and easy access to spare parts. |

Tip: Always pick an APFC system that fits your needs for the best results.

You have learned how automatic power factor controllers help your system. These devices help you use energy better. They save you money and help your machines last longer. You also help the planet by using less energy. Here are the main benefits:

Benefit | Description |

|---|---|

Lower bills | You get your money back in two years |

Better energy use | You waste less and have more power |

Longer equipment life | Your machines get cleaner power |

Smaller carbon footprint | You make less pollution when you use energy |

You can pick an APFC to help manage power and meet your energy goals.

You use an automatic power factor controller to keep your power factor high. The device checks your system and switches capacitors on or off to save energy and lower costs.

You see low power factor readings on your meter. Your electric bills go up. Machines run hot or slow. If you notice these signs, you should consider an APFC system.

You can install small APFC panels if you know basic wiring. For large systems, you should call a licensed electrician. Safety matters when you work with high voltage.

Type | Switching Method | Best Use Case |

|---|---|---|

Contactor-Based | Mechanical | Steady loads |

Thyristor-Based | Electronic | Fast-changing loads |

You should check your APFC system every month. Regular checks help you find problems early and keep your system working well.